Direct Lithium Extraction: Empowering a future of clean technologies

- Shanmukh Bachhu

- Jun 9, 2024

- 3 min read

Image by Alexander Schimmeck on Unsplash

Current methods of extraction and processing of Lithium are slow, resource intensive, and cause extreme environmental damage. Direct Lithium Extraction, or DLE, stops that problem.

To see the engineering breakthrough of DLE we must look at the condition lithium extraction was in before its existence. Before DLE, Brine was pumped into evaporation ponds, then it would be refined with the end product - lithium. This process could take several months to years and required large amounts of land and water. Combined with these environmental impacts it often caused air pollution through its refining process and its toxic waste hurt ecosystems.

DLE fixed this problem.

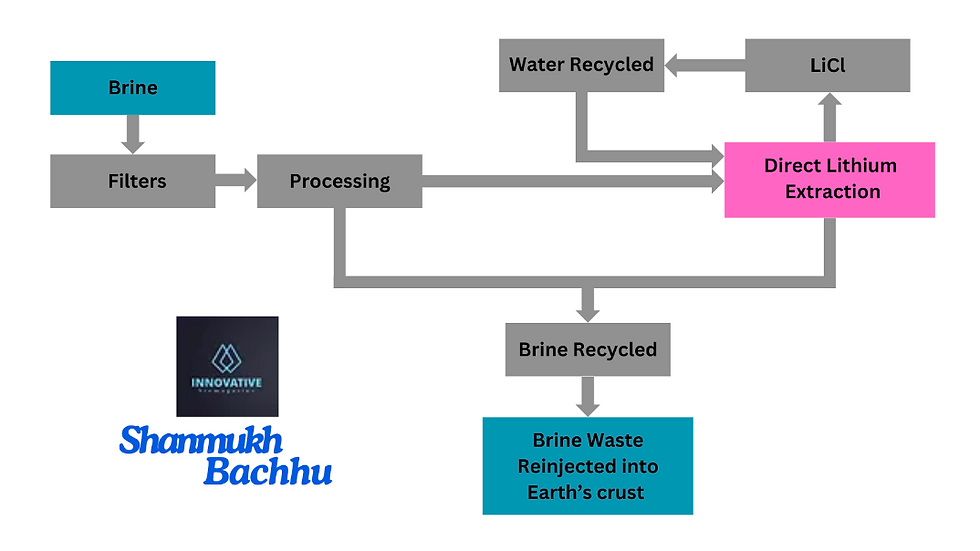

Image by Shanmukh Bachhu

Its Advancements

This new process reduces emissions by 50%.

Traditional methods used up to 2200 mT (metric tons) of water, DLE uses less than 20 mT of water.

DLE is cost effective and produces a greater yield of lithium.

Accesses previously untapped sources of brine through new technology.

Is a system that is faster to set-up rather than traditional lithium extraction methods. Rather than the huge planning of ponds, and refining, DLE works through one plant.

How it Works

Instead of waiting for the liquid and lithium to separate on its own, DLE pumps the brine into a chamber where chemical processes or membranes separate the lithium from the brine. The main variety between companies and products is this separation process. DLE just means directly pulling out the brine, but to separate it is another story.

One of the current and most popular methods for DLE is the use of adsorbents. These adsorbents allow the brine to pass through a membrane that has an absorbent that captures only LiCl, and allows other metals to pass through. A company known as Liliac Solutions is testing its own process for DLE: Ion Exchange. This process uses a ceramic that directly absorbs lithium ions from the brine while releasing a proton. Then this ceramic is flushed with hydrochloric acid, which results in LiCl being the product, which can be processed into batteries. This whole process takes around an hour, which is a major improvement, considering previous methods of lithium extraction took around a year.

The Problems

With all good comes bad, and lithium has many potential downsides. The byproduct of DLE is a concentrated liquid filled with chemicals, salt, and byproducts from the process that can damage ecosystems and the nature around it. A solution to this problem is putting this concentrated liquid back to the source, but that further pollutes the liquid long-term, and reduces the longevity of lithium extraction. Another problem faced by companies is water. Lithium Extraction requires a lot of water, and in areas like Southern California, this amount of water needed reduces the amount of drinking water for locals. A solution to this is recycling the water, which has been done by many companies, but the overall plant will still need thousands of metric tons of this resource over the countless years of its operation.

It is important to note that DLE still doesnt make up the majority of lithium extraction, still to this day, mining for lithium remains as the majority percentage of lithium extraction, making up 60% of all methods of lithium extraction. Traditional evaporation ponds make up 15% and DLE makes up 25%. This means, companies still need to advance DLE technologies to beat up the popularity of traditional mining of lithium. Traditional mining of lithium is very costly, takes a lot of time, and doesn't last a large amount of time.

Furthermore, we need more research, and lab coat jobs to turn DLE to the potential it could be, a method to revolutionize our growing technological society.

To learn more about why lithium is important, check out another article from the same author!

Works Cited:

Stower, Holly. (2023, July 25). Direct Lithium Extraction: New Technologies to Disrupt Traditional Refining and Mining.

CNBC. (2023, June 5). Why The EV Industry Is Betting On This Lithium Mining Breakthrough. https://www.youtube.com/watch?v=oXr3UgM9SVU&ab_channel=CNBC